Anúncios

The electric motor is key in modern EVs, turning battery power into wheel motion efficiently.

EVs combine motors with electronics and cooling systems. This helps meet power needs while driving.

Automakers choose between 400V or 800V setups to get the right mix of charging speed and motor performance.

Motor and inverter efficiencies usually are above 85–95 percent at their best. This helps EVs go further than gas cars.

Anúncios

The electric motor works by magnetic forces between a stator and a rotor, creating spin.

The type of inverter and how the system is cooled greatly impact motor performance and distance traveled.

Using 800V systems means less current is needed for the same power. This cuts down on losses and requires lighter cables.

Electric motors are widely used in cars, trucks, and machines where efficient, compact power is needed.

Understanding the Concept: Old Way vs New Way of Vehicle Propulsion

In traditional cars, the engine has a lot of parts that work together. Pistons, a crankshaft, and a gearbox are some of these parts. These parts need oils, filters, and regular checks. Gas engines are only about 20–30% efficient when driving.

Anúncios

Electric vehicles use a battery, electronics, and an electric motor instead. Electricity moves from the battery, through an inverter, to the motor. This simpler design means less maintenance and fewer parts to worry about.

Electric vehicles also have a cool feature called regenerative braking. When you slow down, the motor helps charge the battery. This makes the electric motor more efficient, adds range, and is something gas cars can’t do.

Filling up your car is different with EVs. Gas stations are quick and everywhere, but charging an EV has more options. You can charge at home or work slowly, or use a fast charger on the highway. Some chargers even let cars send power back to the grid.

| Aspect | Internal Combustion Engine | Electric Powertrain |

|---|---|---|

| Primary energy carrier | Liquid hydrocarbons (gasoline, diesel) | Electrical energy stored in traction battery |

| Power delivery path | Multi-stage mechanical: crank, gearbox, differential | Electrical: inverter to electric motor, single-speed reduction |

| Maintenance needs | Frequent fluids and filters, timed services | Lower scheduled maintenance, fewer consumables |

| Energy recovery | None during braking; heat loss | Regenerative braking captures energy to battery |

| Efficiency (typical) | 20–30% tank-to-wheel for gasoline | Higher system efficiency; electric motor efficiency improves usable range |

| Environmental considerations | Tailpipe emissions present; fuel extraction impacts | No tailpipe emissions; lifecycle focus on battery materials and recycling |

| Infrastructure implications | Established refueling networks | Charging ecosystems with home, public AC and DC fast options |

Lifecycle trade-offs matter when comparing propulsion types. EVs remove tailpipe emissions but introduce impacts from mining lithium, nickel, and cobalt. Aiming to recycle and reuse batteries helps lower their environmental and resource costs.

Workflow: How an EV Powertrain Converts Electricity to Motion

The power flow in an electric vehicle starts with the traction battery. It uses lithium-ion packs with common voltages like 400V or 800V. The cells are arranged to meet both voltage needs and driving range.

The Battery Management System keeps an eye on cell voltages and temperatures. It also looks after the state-of-charge and health. This system is key for ensuring the battery lasts long and meets car makers’ standards.

High-voltage DC power is lowered by a DC/DC converter to power the car’s systems. This powers things like lights and the entertainment system. The main battery pack drives the car forward.

The traction inverter changes DC into AC using semiconductor switches. It uses smart algorithms for a smooth ride. This makes sure the car accelerates smoothly.

An electric motor then takes this AC to create motion. This motion turns into torque that moves the car’s wheels. A gear reducer or transmission helps with this process.

Regeneration captures energy when the car slows down. The inverter turns it back into power for the battery. An onboard charger changes outside power to charge the battery. Some cars combine this with the inverter.

Different types of motors change how the car handles and uses energy. The choice of motor affects how well the car runs and how it brakes. It also influences the car’s warmth.

Designers pick motors based on the car’s job, from city cars to big trucks. Still, the main steps from battery to wheels are the same. The components change based on the car’s needs.

electric motor

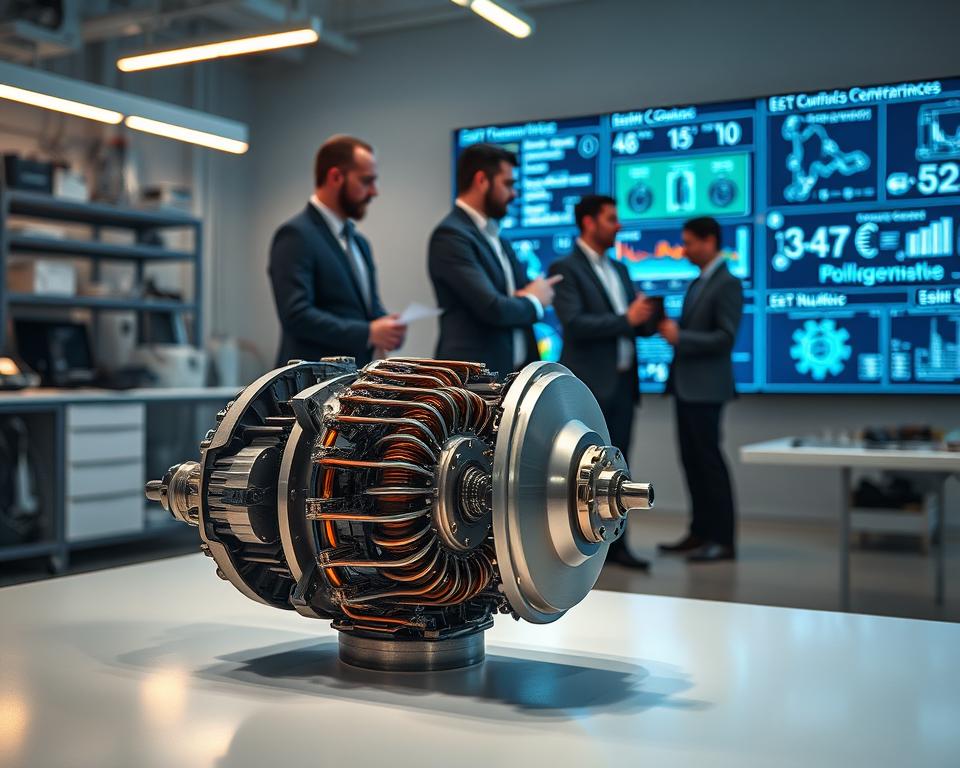

At the core of every EV (Electric Vehicle) is the electric motor. This part explores how it works, the different types you’ll find, and how engineers measure its performance. We aim to clear up any confusion about selecting, using, and maintaining electric motors.

Fundamental parts and operation

Electric motors in vehicles mainly have three key parts: a stator, a rotor, and bearings. The stator remains fixed and uses windings powered by AC to produce a rotating magnetic field.

The rotor, which turns, can have magnets or conductive bars. Motors with permanent magnets sync with the stator for efficient torque. Those with induction rotors use induced currents plus a little lag to create turning force.

Bearings let the rotor spin smoothly. They need to be well-sealed and lubricated, especially for fast spinning. The motor also has cooling systems near the stator to avoid overheating during extended use.

Common architectures used in EVs

In many passenger EVs, like those from Ford and Volkswagen, you’ll find permanent magnet synchronous motors. They’re preferred for their high power in a small package, offering great torque when taking off.

Three-phase AC induction motors are praised for their durability. For example, Tesla’s early Model S cars used them for their simplicity and heat resistance.

Brushless DC motors use magnets and don’t require physical contacts for power, which makes them efficient and low on upkeep. They’re used both for moving the car and in auxiliary systems.

Switched reluctance motors avoid using magnets and have a simple design that withstands heat well, making them cost-effective for certain uses. They’re considered suitable for budget-friendly, high-temperature applications.

Key performance metrics

Torque-speed curves show how well a motor accelerates and climbs. High peak torque means better starts, while continuous torque affects long-term performance like hill climbs or towing.

Motor power, measured in kilowatts, comes in continuous and peak types. Continuous power, limited by how well the motor is cooled, directly impacts real-world efficiency.

Efficiency maps help engineers understand losses at various speeds and loads. This information is crucial for selecting battery sizes and adjusting the inverter for optimal range and reduced heat strain.

| Metric | Why it matters | Typical range (passenger EV) | Impact on operation |

|---|---|---|---|

| Peak torque (Nm) | Launch and short-term acceleration | 200–600 | Improves 0–60 times, demands high transient current |

| Continuous power (kW) | Sustained performance and gradeability | 50–200 | Limited by cooling; drives battery sizing |

| Efficiency (%) | Energy use per mile | 85–97 | Higher efficiency reduces battery drain and increases range |

| Thermal limit (°C) | Safe operating envelope | 120–180 | Dictates duty cycles and cooling system needs |

| Control method | Torque precision and response | FOC / Sensorless | Field-oriented control yields tight torque control and better electric motor efficiency |

| Service interval | Maintenance planning | 5,000–50,000 miles (bearing/lubricant dependent) | Regular checks extend life and reduce electric motor maintenance costs |

Key Components of an EV Powertrain and Their Roles

The electric vehicle powertrain combines important systems to make the vehicle move. Each part has its own job focusing on safety and performance. Let’s look at the main parts like the battery, power electronics, and cooling systems.

Traction battery pack and BMS

Lithium-ion cells are used in modern traction battery packs. They come together to support 400V or 800V setups depending on the car’s needs. These packs are built tough for safety with added protection and monitoring.

The battery management system (BMS) keeps an eye on each cell’s voltage and temperature. It makes sure the battery operates safely and lasts a long time by balancing the cells. This system is key in preventing damage by monitoring for any safety risks.

Traction inverter and power electronics controller

The traction inverter changes direct current (DC) from the battery into alternating current (AC) for the motor. It includes parts that filter out interference and regulate power flow. Advanced materials like Silicon carbide (SiC) are used in high-end cars for better performance.

The software controlling this process is crucial. A well-designed inverter can reduce energy lost as heat and make the motor run smoother.

Onboard charger and charge port

The onboard AC charger can handle different power inputs to recharge the battery. DC fast charging, on the other hand, powers up the battery quicker using special plugs. Some systems combine the inverter and charger to cut down on weight and cost.

How a car connects to charging stations affects charging speed and convenience. The design influences how quickly and reliably a car can recharge.

DC/DC converter and auxiliary battery

A DC/DC converter reduces high voltage from the main battery for car accessories. It keeps the smaller 12V battery charged while making sure everything stays safely separated. The design can handle sudden power needs and help avoid frequent repairs caused by low-voltage issues.

Strong design here matters for handling power spikes and reducing the need for motor repairs.

Thermal system and transmission

Cooling systems work to keep the battery, inverter, and motor at the right temperature. Proper cooling ensures these parts work well and last longer. Most electric vehicles use a simple gear system for efficiency. Some high-performance cars might use a more complex system for better speed or acceleration.

Good thermal and mechanical design can ease stress on parts, which helps reduce maintenance needs.

| Component | Primary Role | Key Features |

|---|---|---|

| Traction battery & BMS | Energy storage and cell safety | Modules of Li-ion cells, cell balancing, SOC estimation, crash protection |

| Traction inverter | DC-to-AC conversion and torque control | Sinusoidal PWM, IGBT or SiC MOSFETs, DC-link caps, EMI filters |

| Onboard charger & charge port | AC charging and interface to DC fast chargers | 3.3–11 kW AC chargers, CCS/CHAdeMO support, integrated inverter-charger in some models |

| DC/DC converter & 12V battery | Low-voltage supply for accessories and control systems | Galvanic isolation options, redundancy, 12V battery charging |

| Thermal system & transmission | Temperature control and torque delivery to wheels | Liquid cooling loops, pumps, single-speed reduction or two-gear setups |

These EV components are crucial in making electric cars run smoothly. Focusing on modular design and quality control can increase how long cars stay on the road. This know-how also helps industries outside of automotive by improving how motors are used and maintained.

Key Options: Comparison of Motor and Powertrain Technologies

Choosing electric motor types affects a vehicle’s weight, cost, and how it performs. Permanent Magnet Synchronous Motors (PMSM) offer lots of power in a small space and work very efficiently. Companies like Tesla and Volkswagen prefer PMSM because they fit well in cars and do great in the city and on highways.

Three-phase AC induction motors don’t use permanent magnets, avoiding the need for rare-earth elements. They’re tough but may require more materials to offer similar power as motors with magnets. It’s important to consider the balance between size and cost when looking at these motors.

Brushless DC motors are good for small spaces and need little upkeep. They work reliably and pair well with electronics to improve performance and efficiency.

Switch reluctance motors are built without magnets in the rotor, making them cheaper and versatile. Though they were once known for being noisy and hard to control, new technologies have made these issues less of a problem.

Choosing the right traction inverter changes how a drive feels and its efficiency. IGBT-based systems are well-known and affordable at slower speeds. Silicon carbide (SiC) MOSFET inverters, on the other hand, work faster, reduce loss, and help make motors more efficient by using smaller components.

Integrated inverter-onboard charger setups combine driving and charging functions, saving space and possibly costs. However, designers need to carefully think about how these systems manage heat and can be serviced.

| Option | Strengths | Trade-offs |

|---|---|---|

| PMSM | High efficiency, high power density, strong torque | Requires rare-earth magnets, temperature sensitivity |

| AC Induction | Magnet-free, robust, proven in heavy use | Heavier, higher material use for same power |

| BLDC | Compact, low maintenance, excellent for auxiliaries | Requires precise electronic control |

| SRM | Simple rotor, low rare-earth dependency, wide range | Historically noisy, needs advanced control |

| IGBT Inverter | Mature technology, cost-effective at lower switching speeds | Higher switching losses than SiC at high frequency |

| SiC MOSFET Inverter | Lower losses, higher efficiency, smaller passive parts | Higher component cost, evolving supply chain |

| Integrated Inverter-ONC | Fewer parts, packaging and potential cost savings | Complex thermal design and service access |

When choosing a motor and inverter type, think about the car’s range, weight, and overall costs. Fleet managers and engineers should aim for motors that meet their efficiency goals and work well day to day. This helps narrow down choices and clearly shows the difference between initial costs and what you save later on.

Efficiency: How Electric Motors Improve EV Range and Performance

Moving from internal combustion engines to electric power changes how cars use energy. Electric motors work more efficiently and together with precise inverters, they help EVs turn more stored energy into motion. This part talks about the benefits of such efficiency, the decisions engineers must make, and how these choices affect the battery and car’s weight.

Electric drivetrains manage energy differently than those using gasoline. They can be more than 85 percent efficient with their combined motor and inverter. Gasoline engines, however, usually reach just 25 to 30 percent efficiency. So, electric cars waste less energy and can go further on the same amount of stored energy.

In cities, where cars stop and start a lot, regenerative braking is crucial. This system can get back up to 70 percent of the energy used during braking under the best conditions. This means the car uses less energy overall and needs less from the battery in city driving.

Selecting the right motor and inverter can affect a car’s efficiency at different speeds and loads. Permanent magnet motors are great for high-efficiency cruising and powerful density, helping with highway driving. Induction motors, while versatile, might need more complex controls to reach the same efficiency at steady speeds.

New technology in inverter design is also making a big difference. Silicon carbide inverters, for example, have fewer losses and can handle higher frequencies than older designs. This means the car can run longer on a single battery charge because it loses less power.

But it’s not just about having the best peak efficiency numbers. Engineers must consider how efficient the motor and inverter are during typical use to decide on the battery size. Smaller batteries can reduce the car’s weight, making it even more efficient. They use special maps and simulations to figure out how these parts can make the car go further.

Below is a summary of how these factors typically impact efficiency and involve certain engineering choices.

| Factor | Typical Effect on Range | Design Trade-off |

|---|---|---|

| Motor + inverter peak efficiency (85–95%) | Raises usable range per kWh; reduces fuel-equivalent consumption | Choose PMSM for cruising efficiency or induction for broad-load flexibility |

| Regenerative braking (up to 60–70% recapture) | Large reduction in urban energy use; extends city range | Regeneration hardware and software add cost and control complexity |

| SiC versus IGBT inverters | SiC lowers switching losses, improves thermal margins, increases range | SiC has higher component cost but reduces cooling needs and weight |

| Motor selection (PMSM vs induction) | PMSM improves highway efficiency; induction offers robustness at varied loads | Permanent magnets add material cost and supply-chain considerations |

| Reduced battery capacity enabled by efficiency gains | Lower mass and cost; improved handling and lifecycle impacts | Requires accurate simulation to avoid under-sizing for real-world use |

Electric Motor Applications: From Passenger EVs to Industrial Electric Motors

Electric propulsion is now found in personal cars, commercial fleets, and heavy machinery. Each electric motor application needs specific trade-offs in power, cooling, and packaging. Fleet managers, OEM engineers, and maintenance teams need to know which motor is best for their needs.

Passenger and light-commercial vehicles prefer smaller, high-efficiency motors. Permanent magnet synchronous motors (PMSM) are widely used because they extend the driving range. This is why brands like Tesla and Hyundai choose them. Dual-motor systems offer torque vectoring, improving handling and efficiency.

Heavy-duty and commercial platforms need motors that can power through continuously with strong cooling systems. For instance, trucks and buses made by Volvo and Cummins have motors built for constant use and quick charging. They use modular parts to make repairs faster and easier.

Passenger and commercial vehicles

In passenger and commercial vehicles, energy efficiency and compact design are key. PMSM and advanced magnet designs are top choices for their efficiency. The goal is to pack more power into less space, using smaller inverters and achieving high power-to-weight ratios.

Industrial electric motors and vehicle-adjacent uses

Industrial motors take cues from vehicle motors, including strong power electronics and cooling techniques. They’re used in material handling, cranes, and equipment by companies like Caterpillar and Komatsu. Upgrading older machines with new motors cuts emissions and maintenance costs.

Emerging use cases and V2X integration

Bidirectional charging creates opportunities for EV owners and energy companies. It requires the right chargers and agreements for vehicle-to-grid and vehicle-to-home use. This turns parked EVs into energy sources, helping with energy supply and reducing costs during peak times.

| Application | Primary Needs | Common Motor Types | Service and Repair Notes |

|---|---|---|---|

| Passenger EVs | High efficiency, low weight, compact packaging | PMSM, BLDC for compact models | Routine diagnostics focus on inverter health and bearing wear; electric motor repair often involves inverter reflash and rotor inspection |

| Commercial Vehicles | Continuous power, thermal management, modularity | Induction motors, PMSM with heavy-duty cooling | Cooling system maintenance and power electronics service are common; modular motors ease field replacement |

| Industrial Equipment | Torque at low speed, durability, retrofit capability | Synchronous motors, large BLDC | Maintenance centers handle rewinds, bearing replacement, and controller upgrades; industrial electric motors benefit from predictive maintenance |

| V2X & Stationary Storage | Bidirectional power flow, communication standards | Vehicle inverter systems adapted for grid use | Software updates and charger diagnostics are typical; repair often centers on power electronics and connector integrity |

Electric Motor Types: Strengths, Weaknesses, and Typical Use Cases

Choosing the right electric motor impacts its efficiency, cost, and how often it needs service. This guide gives a quick look at popular motors, their pros and cons, and their best uses. We cover their durability, heat limits, torque, and maintenance needs.

PMSM

Permanent magnet synchronous motors (PMSM) offer lots of torque and great efficiency when cruising. Automakers like Volkswagen Group and Hyundai/Kia use them in electric vehicles (EVs) and high-performance cars. This is because they’re light and help cars go farther on a charge.

But, they need rare-earth magnets, like neodymium, and they don’t like high heat. It could make them lose their magnetism. To keep them in good shape, they get checked for heat issues and have their inverters adjusted.

Induction motor

Induction motors don’t use permanent magnets, so they’re simpler and less affected by market price changes. Tesla’s early Model S and Model X cars used this tech. It’s known for strong traction and lasting a long time in industrial use.

They’re a bit less efficient in some situations and heavier for the power they offer. Their care mainly involves looking at bearings, cooling systems, and tweaking software to cut losses.

BLDC and SRM

BLDC motors are great because they don’t need much upkeep and work reliably, thanks to electronic commutation. You’ll find them in smaller systems, bikes, and in compact vehicles where reliable performance is key.

SRM motors don’t need magnets and are good with high temperatures, which keeps costs down. However, they can be loud and their torque can be uneven without smart control. So, they usually need extra work on noise control and fine-tuning for smooth running.

| Motor Type | Strengths | Weaknesses | Typical Use | Electric Motor Maintenance Focus |

|---|---|---|---|---|

| PMSM | High torque density; excellent cruising efficiency; compact | Needs rare-earth magnets; temperature-driven demagnetization risk | Mainstream passenger EVs; high-performance models | Thermal checks; inverter tuning; magnet protection |

| Induction | No permanent magnets; durable; cost-stable for some ranges | Slightly lower efficiency in parts of the map; heavier | Earlier Tesla traction; industrial traction | Bearing inspection; cooling maintenance; loss optimization |

| BLDC | Low maintenance; reliable electronic commutation | Packaging and thermal handling vary by design | Auxiliary motors; compact traction; two-wheelers | Controller firmware updates; thermal path checks |

| SRM | Magnet-free; simple rotor; tolerant of heat and material cost swings | Higher acoustic noise; torque ripple without advanced control | Emerging traction roles; specialized industrial uses | Control algorithm refinement; acoustic mitigation |

When picking an electric motor for a car project, think about how often it’ll be used, weight goals, and repair facilities. The best choice balances the initial cost, overall efficiency, and maintenance needs. This helps meet performance and ownership aims.

Electric Motor Maintenance and Repair Considerations

Modern electric vehicles make us focus on high-voltage systems instead of engine oil and spark plugs. Now, we check things like cooling fluid, cabin filters, and brake fluid. We also look at connectors and safety locks. This approach keeps electric cars running smoothly and lasts longer without needing the frequent check-ups gas cars do.

Routine differences from ICE

Electric cars don’t need many of the mechanical parts gas cars do. You won’t be changing timing belts or oil often. Instead, we focus on keeping the inverter cool and managing the temperature. But, we still need to check on things like bearings and brakes regularly.

Common failure modes and diagnostics

Most problems come from the electric parts getting too hot. Issues like switch faults, worn out capacitors, and damaged windings are common. Also, connectors can corrode, and cables can overheat. We can spot these problems through car data and battery logs.

To figure out what’s wrong, we use car data and the battery system. We look for signs like cell problems, too much current, or overheating. Checking the motor directly, testing the windings, and analyzing vibrations can also spot issues with bearings or insulation.

Repair and service ecosystem in the United States

Car makers like Tesla and Ford are making more places to get EVs fixed. Small garages are learning about high-voltage work too. Fixing high-voltage parts needs special tools and safety steps approved by UL and SAE.

Warranties and battery replacements vary by company. When not using official repair places, make sure to follow rules to keep the car safe and the warranty valid. For tricky repairs, it’s best to use certified experts and proper workshops.

Buying Guide and Product Review Considerations for EV Motors and Powertrains

When picking an electric motor and powertrain, think about everyday use, long trips, and costs. Look beyond the highest numbers. Focus on performance over time, how it manages heat, and its behavior under different driving conditions. These details will help you find the right electric motor for what you need.

Key specs to compare

Look at both continuous and peak power ratings, measured in kilowatts. Continuous ratings matter for long uphill drives or when towing. Also, examine the torque curves to understand how torque varies with RPM. A broad, flat torque band means better acceleration in the city and improved towing.

Check out efficiency maps to spot the efficiency peak of the motor. Decide between a 400V and an 800V system. Higher voltage systems use less current, lose less power, and charge faster. Consider whether you want an integrated inverter for compactness, or separate units, which might be easier to fix.

Real-world performance indicators

Look at range estimates from independent tests for an idea of daily range. Be alert to thermal throttling, which can happen with heavy use, like towing or fast driving. Thermal throttling reduces output over time and can make the motor feel less powerful.

Check if the charging systems match your needs. This includes the onboard AC charger’s kW rating and if it supports DC fast charging. Also, see how well it can regenerate energy in city driving. Reviews from MotorTrend, Edmunds, or Consumer Reports often cover these aspects.

Value and total cost of ownership

Work out the cost per mile by considering efficiency and local power prices. Think about battery life, warranty terms, and replacement policies to gauge long-term costs. Compare savings from fewer maintenance needs versus traditional engines.

Factor in value retention by brand and how easy it is to get service from companies like Tesla, Ford, GM, or Nissan. Also, explore ways to make money from Vehicle-to-Grid services if you can in your area.

Purchase advice checklist

- Prioritize efficiency maps and sustained power for intended use.

- Confirm thermal system adequacy for heavy-duty roles like towing.

- Verify warranty coverage and authorized service network.

- Match voltage architecture to charging infrastructure needs.

- Assess expected savings from lower electric motor maintenance.

| Spec | What to look for | Why it matters |

|---|---|---|

| Continuous vs Peak Power (kW) | High continuous rating for towing; high peak for brief sprints | Determines sustained performance and usable power under load |

| Torque Curve (Nm) | Flat torque across RPM for versatility | Improves acceleration, towing, and drivability |

| Efficiency Map | Large high-efficiency area at typical operating points | Direct impact on electric motor efficiency and range |

| Cooling Method | Liquid cooling preferred for sustained loads | Reduces thermal throttling and preserves performance |

| Voltage Architecture | 400V vs 800V — choose by charging speed and system losses | Affects charging time, inverter design, and efficiency |

| Inverter Integration | Integrated for compactness; separate for easier servicing | Influences weight, packaging, and repairability |

| Weight / Power Density | Higher power density reduces vehicle mass | Improves efficiency, handling, and payload capacity |

| Charging Compatibility | AC kW onboard and DC fast-charge protocol support | Determines usable range on long trips |

| Warranty & Service | Comprehensive coverage and broad dealer network | Limits unexpected costs and simplifies electric motor maintenance |

Final Summary: Why Electric Motors Matter for EV Propulsion and Purchase Decisions

The electric motor is key to an electric vehicle’s efficiency. It delivers high torque and better energy conversion than traditional engines. This means quicker acceleration and a longer range. The choice of motor and inverter, along with the voltage design, impacts the vehicle’s heat management and effectiveness in real-life situations.

It’s important for buyers to choose the right type of motor for how they drive. Whether it’s a PMSM, induction, BLDC, or switched reluctance motor, it affects the car’s efficiency. The kind of inverter and system voltage, like 400V or 800V, also play big roles in how well the car uses energy, how quickly it charges, and overall costs. Looking at these factors closely can help buyers make smarter choices, beyond just the upfront numbers.

Maintaining an electric motor is quite different from caring for a gasoline engine. Electric vehicles have fewer parts that move, which means they usually need less maintenance. However, they do require specific knowledge about high-voltage safety and battery care. Thankfully, service providers in the U.S. are getting better at taking care of EVs and industrial electric motors.

When choosing an EV, look for ones with reliable parts and clear testing results. Also, check if their service centers are easy to get to. This helps ensure the vehicle fits your daily life and keeps unexpected costs low. A smartly picked motor and powertrain system lead to improved performance, lower costs over time, and better value in the long run.